Let's welcome the New Year with some of the tremendous improvements made in the hotel industry in recent years. We just completed our 26th annual symposium and training sessions at the Charleston SC Marriott. As you can guess, in 26 years we have learned a lot about how we want to run our events and what the hotel must do to make it run smoothly.

Since we are quality assurance professionals, the failure-complaint mode is not our style. We use FMEA thinking to anticipate and proactively assure what goes right and prevent what could go wrong. This includes providing the hotel with the event order spreadsheet that details each day's room set up, meals (including special diets), audio-visual equipment, costs, and so forth. Such information is always welcomed by the hotel’s banquet staff who take care of multiple groups simultaneously.

Despite this, there are always a few minor things each year that we did not anticipate. This year, the unseasonably warm sun poured into the meeting foyer and melted our ice cream snack. Instead of chasing down a hotel worker or relaying the problem through the front desk via a house phone as we usually have to do, we were able to get the melted ice cream replaced instantly with a couple of swipes and clicks!

The "Marriott Red Coat Direct” is a mobile device app that the chain has rolled out in recent years. It lets us meeting planners message anything needing immediate attention, from “adjust room temperature,” “too much noise from kitchen,” “need more chairs,” to “a daily statement before the end of the day” and more — all without leaving the meeting room or even talking.

We can't tell you what a relief this was. The reassuring part of this system is that the message is viewed not only by the banquet staff who were assigned to our function but also by their peers and their bosses. This provides multiple eyes and ears to make sure the meeting planner’s Voice of the Customer is heard and taken care of — in real time.

Most important, it allowed us to focus on what mattered most – our attendees – instead of running around looking for help.

We look forward to hearing more success stories by companies listening to their customers not only to handle complaints, but to build into their future offerings.

16 January 2015

17 November 2014

Upcoming Public QFD Courses

— Learn today's best methods and tools

All events listed here will be held at Charleston Marriott in Charleston, South Carolina USA. The 1-day Symposium on December 5, 2014 is complimentary to the course attendees.

Registration Page.

For questions, please contact the QFD Institute.

. . . . . . . . . . . . . . . . . . . . . . .

QFD Green Belt® Certificate Course

December 3–4, 2014 (Wed & Thurs)

QFD Black Belt® Certificate Course

December 8–12, 2014 (Monday - Friday)

If you have attended the above courses more than three years ago, now is the time to refresh your knowledge and skills in these semi-private coaching sessions:

Registration Page.

For questions, please contact the QFD Institute.

. . . . . . . . . . . . . . . . . . . . . . .

QFD Green Belt® Certificate Course

December 3–4, 2014 (Wed & Thurs)

- Your chance to learn Modern Blitz QFD®.

- Learn how to do QFD analysis without the outdated 4-house matrices, without the resource-consuming House of Quality matrix.

- Learn how to do a Gemba and VOC analysis, correctly identify and prioritize customer needs, transform them into design specifications of customer-value and innovative solutions, deploy them throughout your new product/service development process — with agility and efficiency essential to today's lean environment.

- Templates included (modern QFD, AHP, modern House of Quality, Maximum Value Table, and more).

- No Prerequisites.

QFD Black Belt® Certificate Course

December 8–12, 2014 (Monday - Friday)

- Advanced QFD training for DFLS/DFSS black belts and master black belts, trainers, facilitators, innovation leaders, corporate training scouts, and anyone who is inspired to be a project leader.

- Learn the full depth and breadth of Modern Comprehensive QFD, including detailed instructions on how to correctly deploy a House of Quality matrix for its full power, with correct data input and prioritization.

- Learn how to expertly integrate your own process and other quality and design methods such as DFLS, Hoshin, Kansei Engineering, TRIZ, Critical Chain, six sigma DMAIC, StageGates, DFMEA and more.

- Templates included (modern QFD, AHP, modern House of Quality, Maximum Value Table, and more), and over 1,000 pages of training manual.

- Prerequisites: Qualified graduates of the QFD Green Belt® Courses.

If you have attended the above courses more than three years ago, now is the time to refresh your knowledge and skills in these semi-private coaching sessions:

- QFD Green Belt® Update Course is the continuing education for QFD Green Belt® graduates. This half-day course is conveniently scheduled on December 7, 2014, 4 PM - 7:30 PM.

- QFD Black Belt® Update Course is the continuing education for QFD Black Belt® graduates. Attendees of this full-day course on December 7, 2014 receive the latest copy of both QFD Green Belt® and QFD Black Belt® training manuals.

11 November 2014

New Kano Model for better design decisions and hidden market opportunities

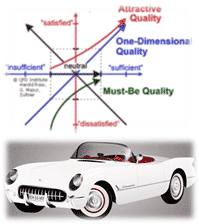

Many people wrongly assume that so-called Kano model (diagram on the right) describes the relationship between customer needs, fulfillment of product features, and satisfaction.

Many people wrongly assume that so-called Kano model (diagram on the right) describes the relationship between customer needs, fulfillment of product features, and satisfaction.The1984 research, "Attractive Quality and Must-Be Quality" by N. Seraku, F. Takahashi, and N. Kano, Ph.D., measured satisfaction merely against the existence or absence of a feature. It did not and does not address customer needs.

Additionally, the Kano categories came from customer survey responding to inverse-paired questions. They were not and are not assigned by product engineers or producers.

The most serious error that people often make is the misleading "curved-arrow" that is often cited as shown in the above diagram. The inverse-paired question yields only two data points: the "if" and the "if not". You can only draw a line (= linear) with two data points. It takes three data points to inscribe a curve! This is why Glenn Mazur (QFD Institute), who translated Kano's original Japanese paper into English over two decades ago, wonders how many people who cite the Kano model actually read their study.

This problems was addressed by Mr. Harold Ross, a now retired General Motors engineer and a director of the QFD Institute. He called this the New Kano Model, which adds the necessary questions to draw the "curve" and use it to reveal hidden market segments and extrapolate better design decisions.

This problems was addressed by Mr. Harold Ross, a now retired General Motors engineer and a director of the QFD Institute. He called this the New Kano Model, which adds the necessary questions to draw the "curve" and use it to reveal hidden market segments and extrapolate better design decisions.Using the Modern QFD tools that are taught in the QFD Black Belt® course, you can then identify the invisible, moving target of customer satisfaction that the original Kano model does not address.

This new methodology will be presented at the 26th Symposium on QFD, December 5, 2014 in Charleston, South Carolina USA. It will include implementation examples of automotive industry, development of marketing and advertising content, as well as identifying clearer performance targets for each customer segment.

Everyone is welcomed at this symposium, regardless of your QFD knowledge.

Here is how to attend.

04 November 2014

New High in Customer Satisfaction

Forget everything you learned about customer satisfaction.

A Chinese noodle shop has found the secret to customer retention, that scores "higher" than any other approach we've seen.

Read here, Sept 24, 2014 CNN World reported by Katie Hunt

A Chinese noodle shop has found the secret to customer retention, that scores "higher" than any other approach we've seen.

Read here, Sept 24, 2014 CNN World reported by Katie Hunt

28 October 2014

Thomson Reuters 2014 Journal Citation Reports® recognizes "Using QFD to Write an ISO Standard"

Writing and publishing implies a level of authority on a particular subject. We say "imply" because it may not always be the case. There are numerous books, papers, and articles that suggest a certain expertise but fall short of delivering it.

The recent advent of self-publishing technology, without peer review, makes it difficult to separate the wheat from the chaff. Even the Quality community is not immune.

That is why it was a pleasant surprise to receive a notification from Francis and Taylor, publishers of the Quality Engineering Journal, saying that a recent article by Glenn Mazur, "Using Quality Function Deployment to Write an ISO Standard for QFD," has been recognized by Thomson Reuters 2014 Journal Citation Reports® for improving Quality Engineering Journal Impact Factors.

Thomson Reuters is a major multinational media and information company based in New York City. Thomson Reuters Journal Citation Reports® measures how many times a particular article has been cited by peers, as an indicator of the article impact on the subject matter. This is what they say on their web page:

Hooray for Glenn Mazur, executive director of the QFD Institute and also one of the contributors of this QFD Blog. He also shares his expertise often in the QFD Institute Newsletter, which is free and you can subscribe from here. He will be speaking at the December 5, 2014 Symposium on QFD.

The recent advent of self-publishing technology, without peer review, makes it difficult to separate the wheat from the chaff. Even the Quality community is not immune.

That is why it was a pleasant surprise to receive a notification from Francis and Taylor, publishers of the Quality Engineering Journal, saying that a recent article by Glenn Mazur, "Using Quality Function Deployment to Write an ISO Standard for QFD," has been recognized by Thomson Reuters 2014 Journal Citation Reports® for improving Quality Engineering Journal Impact Factors.

|

| screen shot of Thomson Reuters JCR |

Thomson Reuters is a major multinational media and information company based in New York City. Thomson Reuters Journal Citation Reports® measures how many times a particular article has been cited by peers, as an indicator of the article impact on the subject matter. This is what they say on their web page:

Hooray for Glenn Mazur, executive director of the QFD Institute and also one of the contributors of this QFD Blog. He also shares his expertise often in the QFD Institute Newsletter, which is free and you can subscribe from here. He will be speaking at the December 5, 2014 Symposium on QFD.

Thomson Reuters® and Journal Citation Reports® are registered marks of Thomson Reuters.

23 October 2014

Healthcare QFD examples - October 30, 2014 in Orlando, Florida

Modern QFD has been used successfully in the healthcare industry, from clinical gemba such as hospitals and medical labs, to health insurance industry and medical device development including Electronic Medical Records.

Modern QFD has been used successfully in the healthcare industry, from clinical gemba such as hospitals and medical labs, to health insurance industry and medical device development including Electronic Medical Records.Healthcare QFD methods and tools will be presented on October 30, 2014 at ASQ Technical Communities Conference in Orlando, Florida USA.

The talk, "Delighting Customers in Health Care Using QFD" (1:45 pm - 2:45 pm), will share the case studies of a hospital, healthcare insurance company, and medical device development to show how you, too, can acquire, analyze, prioritize, and innovate solutions for the Voice of Customer.

We hope you will be able to join us!

17 October 2014

Is it mean to mean different things with the same words?

One strength of Modern Blitz QFD® and its powerful voice of customer analysis toolset is a way to more deeply understand the customer's words, since different cultures, regions, age groups, sexes, and so forth can use the same words to mean different things.

The other day, I was listening to the rock opera Tommy by the Who, and in the song Pinball Wizard is the line "…sure plays a mean pinball." Even though I have heard that song a hundred times or more, it suddenly occurred to me, does that mean he plays average pinball or above average pinball?

If you ask us quality specialists, "mean" means average. If you ask us hippies (the album was released in 1969), "mean" means wickedly good, and certainly better than average. Same word, different meaning depending on who says it and in what context.

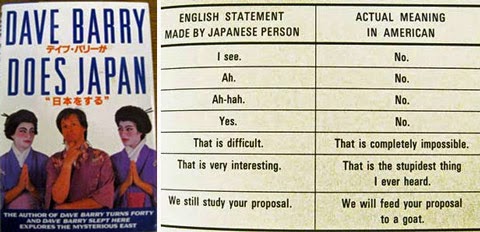

In his hilarious book Dave Barry Does Japan, the author offers a translation table. My favorite is "We will study your proposal" translated into American English as "We will feed your proposal to a goat."

My point is this, QFD should start with the voice of the customer, but that voice must be translated in order to understand its true meaning.

The other day, I was listening to the rock opera Tommy by the Who, and in the song Pinball Wizard is the line "…sure plays a mean pinball." Even though I have heard that song a hundred times or more, it suddenly occurred to me, does that mean he plays average pinball or above average pinball?

If you ask us quality specialists, "mean" means average. If you ask us hippies (the album was released in 1969), "mean" means wickedly good, and certainly better than average. Same word, different meaning depending on who says it and in what context.

In his hilarious book Dave Barry Does Japan, the author offers a translation table. My favorite is "We will study your proposal" translated into American English as "We will feed your proposal to a goat."

My point is this, QFD should start with the voice of the customer, but that voice must be translated in order to understand its true meaning.

13 October 2014

New QFD Group in LinkedIn

The QFD Institute is pleased to launch a new LinkedIn Group devoted to conversations, Q&A, and announcements about QFD activities. It is moderated by the Executive Director, Glenn Mazur.

To join this new group,

While there are other QFD-named groups, it appears they have gone "ghost" or "zombie" where the underlying moderator no longer exists or participates.

This new QFD LinkedIn group is for professionals who are serious about learning and implementing QFD and relevant methodologies for design, quality, new product development, business process innovation, VOC, innovation, etc.

We invite you to ask a question, post a comment, like something, or follow the QFD Institute.

To join this new group,

| 1. You must have a free LinkedIn account, which you can easily join at www.linkedin.com |

| 2. In the search box, type "qfd institute" and select the QFD Institute Group. |

|

| 3. Click "Join" and join the conversation. |

While there are other QFD-named groups, it appears they have gone "ghost" or "zombie" where the underlying moderator no longer exists or participates.

This new QFD LinkedIn group is for professionals who are serious about learning and implementing QFD and relevant methodologies for design, quality, new product development, business process innovation, VOC, innovation, etc.

We invite you to ask a question, post a comment, like something, or follow the QFD Institute.

22 September 2014

Bad customers causing problems? Only sell to good ones, then.

At a dinner party last week, one of my friends who recently retired as an automotive safety engineer was discussing the latest recall in airbags. It reminded me of an Automotive News article I had read decades ago about a seatbelt manufacturer that had to recall millions of seatbelt buckles because the plastic retainer was breaking.

As I recall, the article quoted an employee of one international seatbelt supplier blaming the American customer because they eat fried potatoes and have dogs in their cars. Apparently, the salt, oil, and pet hair was weakening the plastic part.

QFD thinking tells us that if you want to sell in America, your product must be robust to reasonable American use – in this case food and pets in the cars. Otherwise, DON'T sell in America. Blaming the customer moves the responsibility from you, the maker to the customer. If you blame the maker, who has control over your design, you can effect a solution. If you blame the customer, over whom you have no control, the only solution is to get better customers. Good luck with that!

As I recall, the article quoted an employee of one international seatbelt supplier blaming the American customer because they eat fried potatoes and have dogs in their cars. Apparently, the salt, oil, and pet hair was weakening the plastic part.

QFD thinking tells us that if you want to sell in America, your product must be robust to reasonable American use – in this case food and pets in the cars. Otherwise, DON'T sell in America. Blaming the customer moves the responsibility from you, the maker to the customer. If you blame the maker, who has control over your design, you can effect a solution. If you blame the customer, over whom you have no control, the only solution is to get better customers. Good luck with that!

23 August 2014

QFD in Europe - Reporting 2014 QFD activities across EU

2014 has been a big year for QFD in Europe.

Keep up the good work, Europe. I will update you on Turkey soon!

|

| The statue of Poseidon in Gothenburg photo: Historiker/Wiki Commons |

- The spring blossomed with QFD Green Belt® and QFD Black Belt® in-company training sessions in Nuremberg Germany, Prague Czech Republic, and Waterloo Belgium. Several projects are well under way.

- The summer heated up with a June QFD workshop during the International Academy for Quality (IAQ) annual meeting in Stenungsbaden Sweden, using QFD tools to capture the voice of the IAQ membership (including our Chair, Sr. Mary Jean Ryan) in order to explore ways to improve the membership experience. The session was followed by an all-you-can-eat seafood buffet and musical dinner cruise!

- Next was a special Pre-EOQ Congress session in Gothenburg Sweden attended by 37 participants. This included a 2.5 hour QFD White Belt® training session to introduce the new VOC (Voice of the Customer) and AHP (Analytic Hierarchy Process) tools used in Modern Blitz QFD®.

- In the main European Organization for Quality (EOQ) session was a paper on the ISO 16355 standard (new QFD standard).

- The ISO Technical Committee (TC) 69 for Statistical Methods held its annual plenary session in Vienna Austria later in June. We were able to finalize the ISO 16355 draft and launch its commentary phase. Work on Parts 2 and 3 have begun.

- The autumn is ablaze with new events, starting with the 20th International Symposium on QFD (ISQFD) as well as a

QFD Green Belt® course to be held in Istanbul Turkey from September 2 - 5, 2014. This is a great opportunity for readers in EU and ME regions to attend the today's best QFD training and earn an international QFD certificate. - The 2014 Akao Prize® is being awarded to Associate Prof. Jaroslav Machan of the Czech Republic during the ISQFD.

|

| Vienna photo: Eliza0027/Wiki Commons |

Keep up the good work, Europe. I will update you on Turkey soon!

Subscribe to:

Posts (Atom)