In a recent onboard flight magazine, I came across an article recommending things to do in Stockholm. Among the list was the Vasa Museum. I remember visiting it on one of my earliest QFD trips to this beautiful Scandinavian country. It was impressive to see the fully intact 135 foot wooden warship from the 17th century despite it being lost under water for over 300 years.

From my QFD perspective, the ship’s history offered interesting insight to the management style problem discussed in “The unreasonable boss - when executive solutions become design constraints.”

|

| Vasa, fully intact 17th century Swedish warship (photo - wikipedia) |

Vasa was commissioned by King Gustavus Adolphus (1594–1632) to flag the nation’s largest and most powerful naval force at the time. But immediately after leaving the dock on its maiden voyage in 1628, the ship sank in the Baltic Sea.

Why? Too many design changes as after-thoughts, lack of specifications and documentation detailing the ongoing design changes and modifications, unclear division of responsibility, unrealistic schedule demand, the project mission that got blurred by those changes, and stunted communication between the customer (king), producer (shipwright and builder), and operator (naval officers in charge of testing and navigation).

In particular, the changes that the king ordered after the timbers had been cut to size and the ship’s keel had been laid exacerbated the ship’s instability and ballast deficiency. Other late changes also shifted the project mission unwittingly.

For example, adding the second gun deck (after learning Denmark was building such a design) not only increased the weight burden (too many cannons) but also changed the main objectives of naval war tactics (from crippling the enemy ship with firing volleys from one deck and taking over onboard to capsizing the enemy ship by broadside firing from two decks).

|

| decorated stern model of Vasa (photo - wikipedia / Peter Isotalo) |

In those days it was customary for warships to have ornate decorations that glorified the king. Again, many more sculptures were added on Vasa than its original design. Each measuring 10 feet long, you can imagine how heavy 500 sculptures were to the 135 foot ship.

None of the workers and subordinates had the courage to reveal these structural problems to the king, who had issued a threat against anyone causing schedule delay.

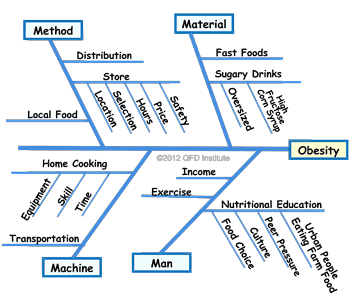

As we discussed in our previous post, Modern Blitz QFD® tools can help analyze and offer solutions to these scenarios.

Readers, can you follow the process described in that post and do your own analysis of the advantages and disadvantages of the king’s orders for the Vasa project? Please share your analysis and questions with us in the comments.